The building industry is becoming more innovative every day. The tools we use to tackle new challenges are constantly evolving—becoming smarter, more efficient, and more powerful.

Since 2015, automating Revit and solving complex BIM challenges has been my main area of focus and passion.

At companies like Royal BAM Group, Strukton, and Spie, I’ve contributed to large-scale projects across the Netherlands, delivering smart solutions through automation.

For infrastructure, utilities, and residential developments, I’ve used Dynamo to streamline workflows, reduce manual tasks, and solve project-specific challenges with precision.

Below are a few examples of challenges I encountered and solved while working on various projects.

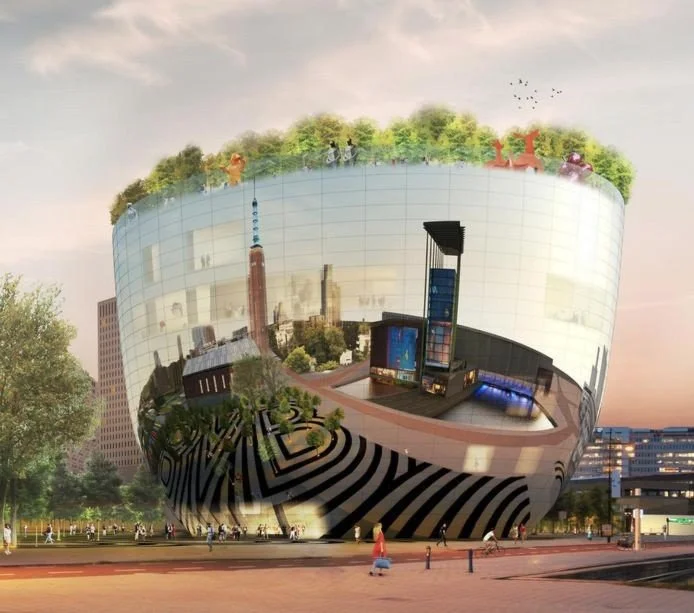

Boijmans Museum

Rotterdam, The Netherlands

The concrete exterior walls of the museum were far from standard. While the outside surface was flat, the interior had to be curved—with a varying radius on each level. This meant that every floor required uniquely shaped wall elements.

Using Dynamo, I was able to automate the generation of these complex wall geometries in under a week, significantly reducing both time and cost for the company.

THTK – Temporary House of Parliament

The Hague, The Netherlands

The temporary building of the Dutch Parliament (Tijdelijk Huis van de Tweede Kamer).

For over three years, I worked full-time on this project, focusing on solving complex challenges and streamlining various BIM processes.

My responsibilities included running model checks with Solibri, supporting coordination efforts, and automating repetitive tasks using Dynamo. I also produced detailed drawings for ceiling coordination and void planning.

DNB – De Nederlandsche Bank

Amsterdam, The Netherlands

At the Dutch central bank renovation project, I continued my work from the THTK project, focusing on automating BIM processes using Dynamo.

Similar challenges required similar solutions—streamlining tasks, improving efficiency, and supporting the project team with smart automation tools.

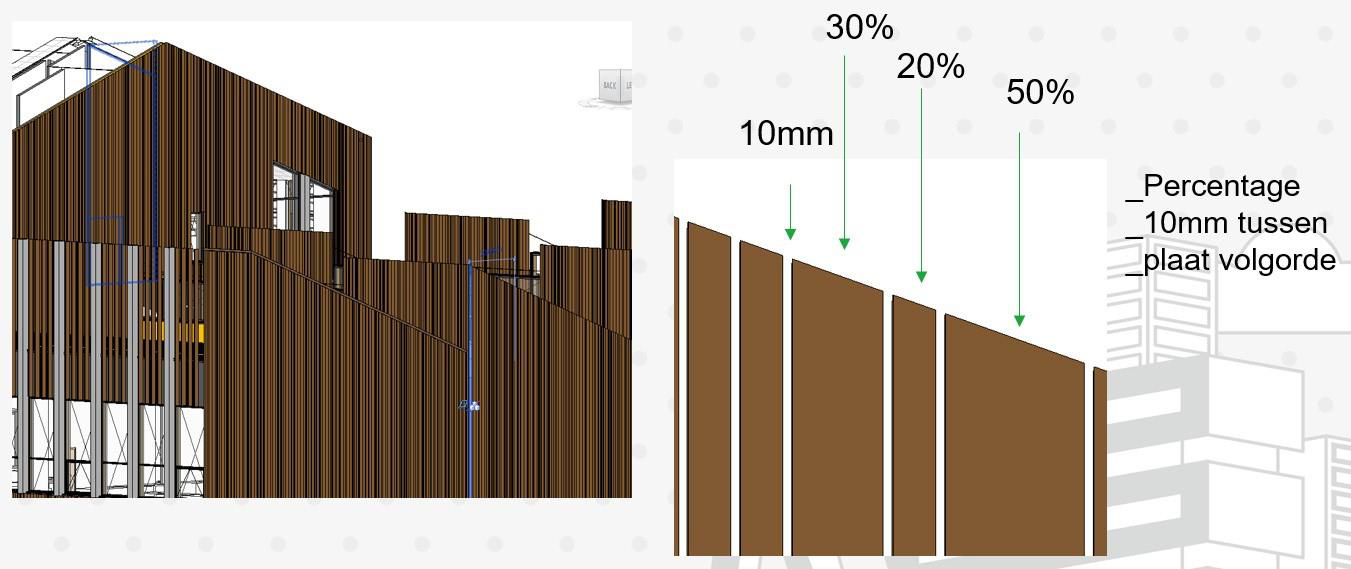

Zernike Innovation Centre

Groningen, The Netherlands

The façade design for this project required three different types of wooden panels, each with a specific width and placement ratio. The panels needed to be positioned with a 10 mm gap between them, and the distribution had to follow precise percentage rules.

Using Dynamo, I automated the placement of Revit families along the façade and generated an Excel schedule with the exact quantities of each panel type required per wall—saving time and improving accuracy in both design and procurement.

Infrastructure Projects

At Royal BAM, I had the opportunity to support several infrastructure projects by automating the generation of complex elements using Dynamo.

Some of these projects included double-curved bridges with specific profiles. In early design phases, I created the main bridge geometries to support concept development. In other cases, I generated specific bridge components based on reference geometries or variable surfaces—speeding up the modeling process and improving precision in design.

Organic Forms

The need to generate organic forms in Revit sparked my interest in exploring the world of computational design and programming. I began by researching methods to generate curves based on catenary and hyperbolic formulas using Dynamo, diving deep into the potential of parametric design to create complex, organic shapes.

Schiphol airport / Amsterdam

In large-scale projects, elements often require data to be filled based on their type or other properties. This process is time-consuming and prone to errors, leading to the risk of incorrect data entry. Using Dynamo, I automated the extraction and population of client-required data, significantly saving time and reducing costs.

Other Challenges Solved Using Dynamo:

Split a master template into multiple templates, automatically adjusting and cleaning them.

Automated the creation of foundations, floors, and walls in a residential project based on data from an Excel file.

Generated GSI files for loading into a total station, enabling precise coordinate mapping of objects on the building site.

Checked and compared parameter values of clashing elements.

Automated the generation of 3D and 2D views in Revit.

Extracted quantities based on clash detections.

Generated gutters automatically based on variable floor surfaces.

Created and exported IFC files automatically.

Streamlined sheet generation processes in Revit.

Generated unique element codes based on position and level.

Developed and ran multiple scripts for managing voids (sparingen) processes.

Automated unique room code generation.

Created dummy PDF files based on data from Excel sheets.

Applied different insulation types and thicknesses to multiple installation families.

The list of challenges I’ve tackled is much longer—and continues to grow every day.

Feel free to reach out if you’d like to discuss any challenges you're facing, ideas you want to explore, or tools you'd like to develop for your team.